Hybar, a newly formed company, has successfully raised $700 million of debt and equity financing to build, start up, and operate an environmentally sustainable scrap metal recycling steel rebar mill. The equity portion of the financing was led by TPG Rise Climate, the dedicated climate investing strategy of TPG's global impact investing platform TPG Rise, and Global Principal Partners, the investment entity used by Hybar's senior management team.

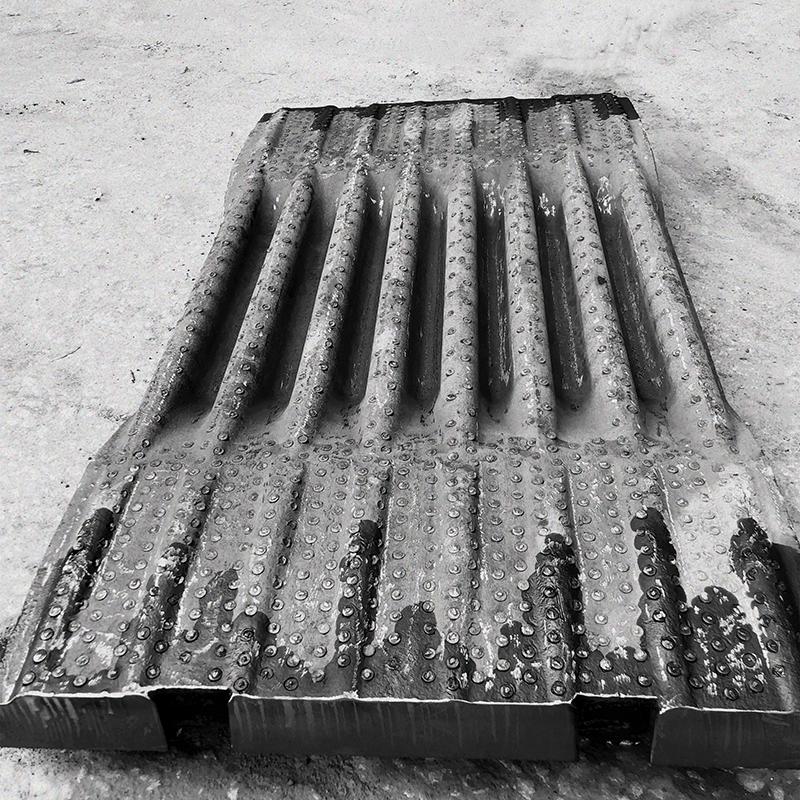

Of the $700 million raised, $470 million will be spent to build the rebar mill. The remainder of the financing will be used to start up and operate the mill and pay certain debt service costs during construction. The mill, which is expected to take 22 months to construct, is being built in northeast Arkansas on a 1,300-acre greenfield site with direct access to barge, rail, and truck transportation options. The mill will produce a full complement of rebar that will primarily be used in infrastructure projects. Secondary Jaw Crusher

Hybar's mill technology, including the water treatment facility, is being supplied by SMS Group. The substation is being supplied by Primetals Technologies. Hybar's technology is designed to reduce the amount of energy needed to produce rebar – especially when compared to other rebar mills in North America, many of which were built more than thirty years ago. Hybar's technology will also limit greenhouse gas emissions. Hybar expects its greenhouse gas emissions to be the lowest among all North American steel producers.

Hybar's ability to reduce energy use while limiting greenhouse gas emissions were key drivers leading to Hybar being certified to issue Climate Bonds. Climate Bonds demonstrate compliance with the international Paris Agreement's greenhouse gas emissions targets.

"The Climate Bond certification aligns perfectly with Hybar's plan to offer our customers competitively priced rebar that is also the greenest rebar in the market," said Dave Stickler, Hybar's chief executive officer.

Stickler and his colleague, Ari Levy, Hybar's chief financial officer, have a long and successful track record of investing in, building, and operating scrap metal recycling steel mills in North America.

Hybar's mill will be directly connected to an adjacent solar facility. This will allow the company to know with certainty that during certain periods of the day, the electricity being used to run the mill is being generated from 100 percent renewable sources. Hybar says that no other steel mill in North America is directly connected to a solar field that can supply 100 percent of its power needs. Hybar also has a special rate power contract with Entergy Arkansas, under which Hybar will be able to buy electrical power to supplement the adjacent solar-generated power when needed.

Hybar plans to produce 630,000 tons of rebar annually with approximately 154 employees. The 154-employee figure includes all employees, not just operating employees.

Insight delivered weekly to your inbox

Baum Publications Ltd. 124-2323 Boundary Rd, Vancouver, BC V5M 4V8 Canada

604-291-9900 Toll Free: 1-888-286-3630 Fax: 604-291-1906

© 2024 - Baum Publications Ltd. - All rights reserved. - Privacy Statement - Powered by AX2 Inc .

Manganese Parts We use cookies to enhance your experience. By continuing to visit this site you agree to our use of cookies.